How to Choose the Right Saw Blade For Your Circular Saw

Choosing the right saw blade for your project is easy once you know what to look for. These are a few things to consider when selecting a saw blade for your circular saw.

*This post is sponsored by The Home Depot and contains affiliate links and I will be compensated if you make a purchase after clicking on my links.

One of the questions I get asked the most is ‘How do I choose a saw blade?’; and ‘Is more teeth on a saw blade better?’ Well, the answer is, “It depends.” It depends on a number of factors including the application or what your cutting, the speed at which you’re looking to get things done and what price you’re willing to spend. When you buy a circular saw it typically comes with a general-purpose blade that is more equipped to tackle ripping and rough framing type jobs. The blade has fewer teeth and the cut is often rough, leaving a lot of rough tor material at the edges. Buyers/users are expected to change out the blade to accommodate the job. So in order to ensure that you have selected the right circular saw blade for the job consider the following factors.

Things to Consider

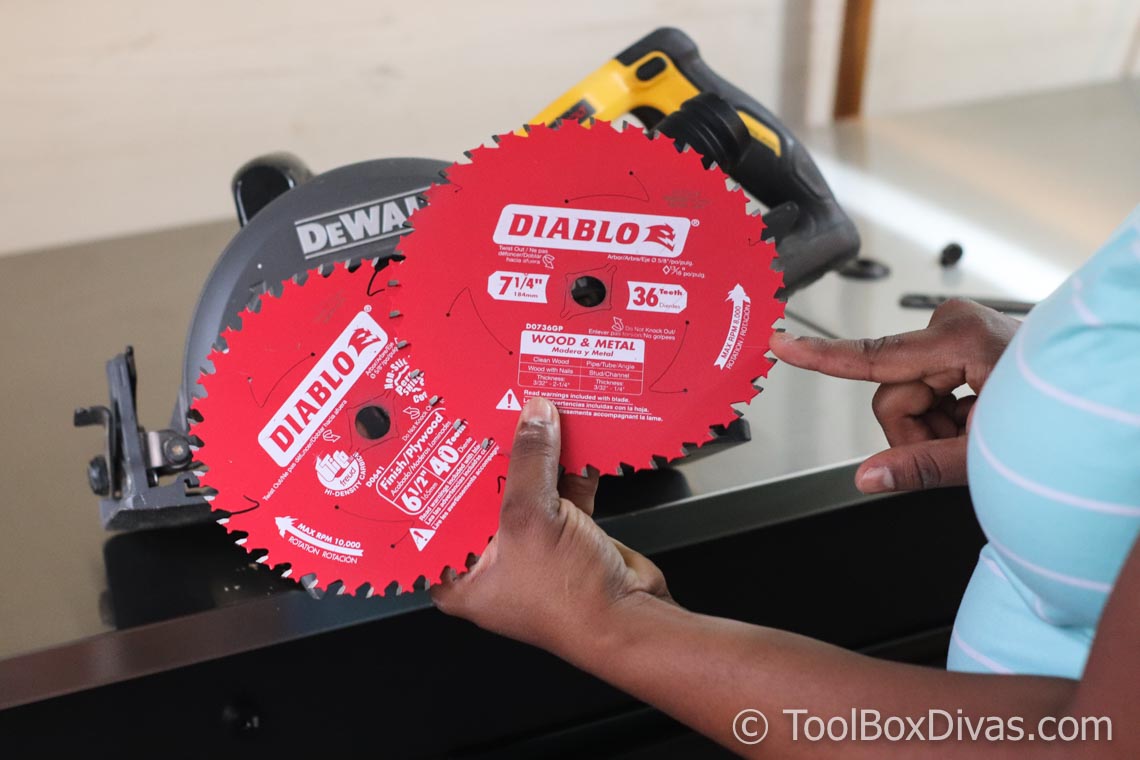

- Blade Size: First thing’s first, what size is your circular saw? Circular saws are generally 6.5 inches or 7.25 inches, while table and miter saws are 10 -12 inches. Select the saw blade the matches the size of your saw. 6.5in. blades go with 6.5 in. saws etc.

- Application: What are you cutting? The material that is being cut is just as important as knowing the size of the blade. Typically, unless stated on the blade, a wood cutting blade isn’t meant to cut metal.

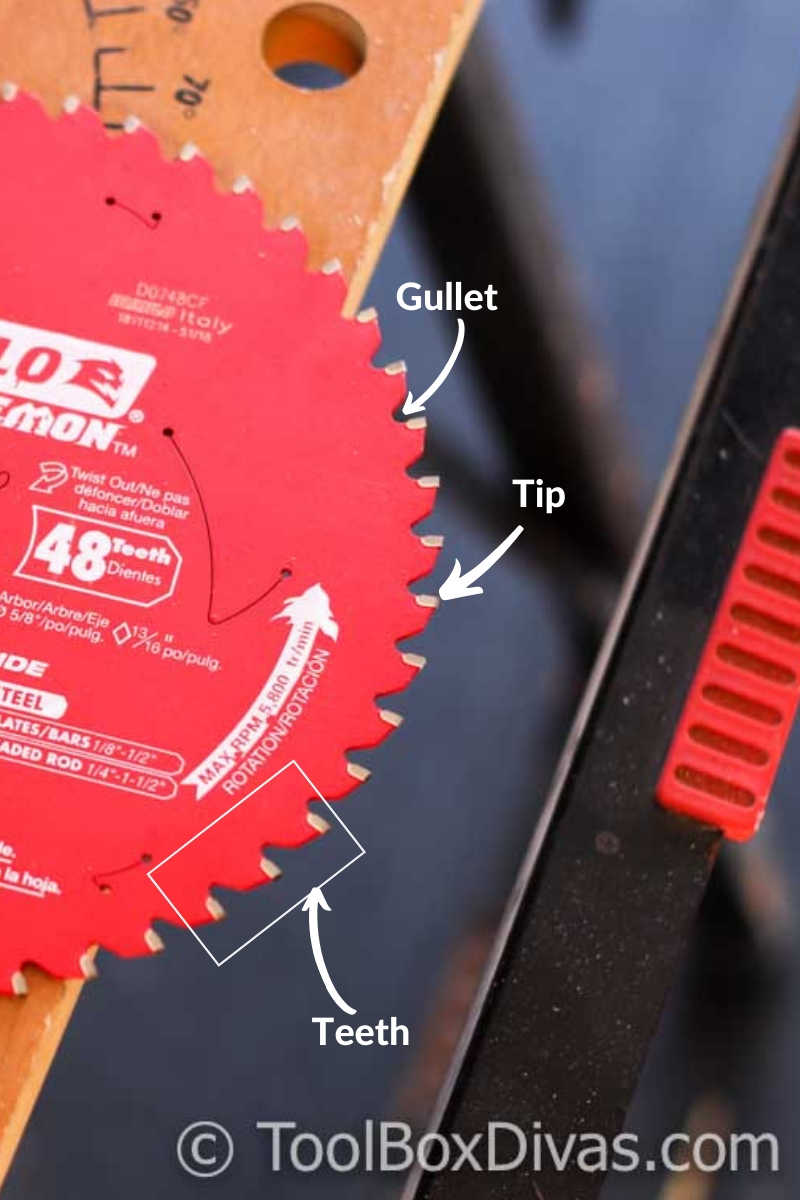

- Teeth: The number of teeth on a blade is an indicator of the speed in which the blade will cut. The lower tooth count cuts faster but the cut is rougher. This is good for rip cuts (cuts that go with the grain). Higher tooth count cuts slower and there is more friction. However, the cut leaves a nicer finish. This is good for making crosscuts (Going against the grain).

- Gullet: This is the curved area between the teeth. It’s a relief area to store material as it’s cutaway It helps prevent the blade from burning the material as you cut it. For faster rip cuts, you’ll want this area to be larger. Cross-cutting blades have smaller gullets.

- Kerf: It’s the thickness of the blade. An ultra-thin kerf cuts the fastest and removes less material so less wood is wasted. It is also known to draw less energy and prolong the battery life of the saw.

- Other things to consider: There are a few other things to consider when selecting a blade for your circular saw. However, given the manufacturer of the blade and the blade type, it will differ largely due to the advancements in the overall production of new blades.

-

- Anti-friction coating on blade: This feature reduces blade friction and it from overheating. It helps create a longer blade life span and usage. works great cleaning yo build-up from pressure-treated wood.

- Anti-vibration slots: These slots are aimed at reducing blade vibration.

- Steel blades: Blades with steel tips normally have a lot of teeth and is geared toward cutting plywood. However, steel dulls quickly.

- Carbide tips: Blades with carbide tips stay sharp longer so it has a longer life span.

- Diamond tips: Diamond tip blades are super strong for cutting glass, ceramic and concrete material.

- Price: Finally, what are you willing to pay? There’s a slew of blades out there that claim to do a lot of different things. But at the end of the day, it really does come down to what are you willing to pay. Circular saw blades range in price from $6-$8 to $40-$50 for high-end specialty blades.

Recommended blades to keep on hand

I recommend keeping a few circular saw blades on hand that will cover just about any job that may surface in your DIY life. I recommend one for general use, finished plywood and one for metal cutting.

General Use

Diablo 7-1/4 in. x 36 TPI Wood and Metal Carbide Saw Blade

-

- This blade is great for ripping and demolition. It’s a multi-purpose saw blade for cutting clean wood and wood with nails, up to 2-1/4” material thickness and metal ranging from 3/32”-1/4” wall thickness and 1/4”-1” diameter.

- It’s compatible with any 7 1/4″ corded or cordless circular saw.

- It has the new Diablo made TiCo carbide tips, which are specially designed for this blade, coupled with the blades Chamber-Alternate Tooth Design (C-ATB) tooth design provides impact resistance for cutting wood with nails as well as the durability for creating clean, burr-free cuts in metal

Finished Plywood

Diablo 6-1/2 in. x 40-Teeth Finish/Plywood Saw Blade

- This saw blade is compatible with any 6 1/2″ corded or cordless circular saw.

- It cuts 2x lumber, plywood, laminate, melamine, osb, & hardwood and has a super thin laser cut kerf for fast, durable, & clean cuts.

- Constructed with TiCo Hi-Density special-blend carbide, this Diablo blade has 40 teeth to make smooth, finely finished cuts in plywood. The Perma-SHIELD nonstick coating reduces drag while stabilizer vents absorb noise and vibration to keep the blade straight. An ultra-slim kerf produces a thin swath for less material removal and fast, effortless operation in dry or wet lumber.

Diablo 7-1/4 in. x 40-Teeth Finish Saw Blade

Similar to the Diablo 6-1/2 in. x 40-Teeth Finish/Plywood Saw Blade is the Diablo 7-1/4 in. x 40-Teeth Finish Saw Blade compatible with circular saws that are 7 1/4.” The biggest difference is this blade isn’t ideal for wet lumber.

Metal

Diablo 7-1/4 in. x 48 TPI Cermet Steel Demon Ferrous Metal Cutting Saw Blade

- This blade is compatible with any 7 1/4″ corded or cordless circular saw.

- It’s specially formulated Cermet (Ceramic and Metallic blend) teeth provide high heat tolerances and increased hardness for superior wear and ultimate cutting life– up to 40X longer life versus standard carbide-tipped metal cutting saw blades. The blade’s triple chip tooth design provides burr-free finishes that require no-rework and longer cutting life.

- In addition, it’s advanced laser-cut stabilizer vents trap noise and vibration for maximum stability, keeping the blade cool for straight, accurate cuts in metal cutting applications.

For more reviews and tutorials check out these posts:

I acknowledge that The Home Depot is partnering with me to participate in the ProSpective 2018 Campaign. As a part of the Program, I am receiving compensation in the form of products and services, for the purpose of promoting The Home Depot. All expressed opinions and experiences are my own words. My post complies with the Word Of Mouth Marketing Association (WOMMA) Ethics Code and applicable Federal Trade Commission guidelines.

That’s good to know that the circular saw will have several types of blade. I am thinking about cutting some metal with mine, and I only have a general use blade. I’ll have to look at some options to see if I can find a blade to cut metal with.