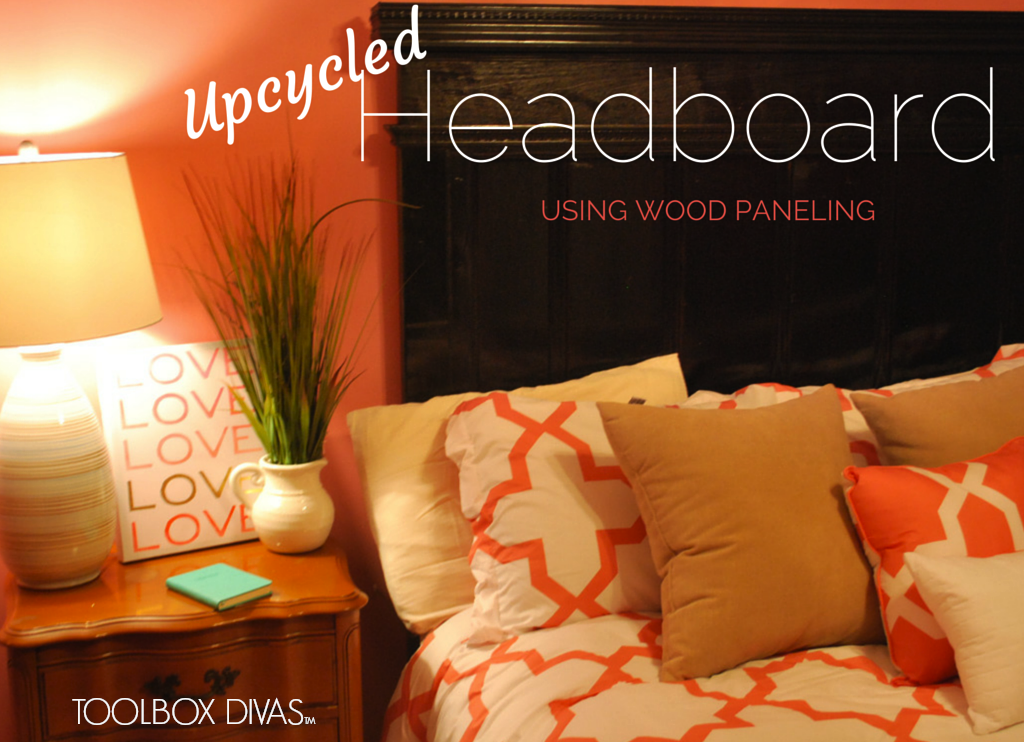

Upcycled Headboard Made With Wood Paneling

This year my goal is to tackle at least one concept or “pin” each month, centered around one room. Every month will be a different room or space. This is the Pinterest Room Challenge. The “Room of the Month” for January is the Bedroom. So when a friend of mine approached me about helping her find an affordable headboard, I decided to take on the challenge of creating a headboard inspired by a “pin” found within the ToolBox Divas Bedroom Inspiration Board.

|

| Pinterest via Found on theturquoisehome.com |

(3/4” in thickness); Each Panel Cut to 26″ in length

Panel) Cut to 55″

the Panel and Legs) Cut to 62″

Cut to 50″

Trim for Panel) Cut to 26″

(Top/Bottom Panel Trim) Cut to 55″

Headboard) cut to 64″

Quarter Round pieces for inside the paneling

Crown Moulding found @ Lowes

Moulding found @ Lowes

Lay out the wood paneling to measure and cut down to 55″ wide and each board down to 26″ in length. To achieve uniformity when cutting down to the 55″ panel width, cut evenly the two end panels.

Connect the panels with a brad nailer and wood glue. You can also use small finishing nails hammering in at an angle or toenailing.

I reinforced everything with wood glue. Always check that the trim is square using a speed square.

Flip the headboard panel over to attach the bottom base of the headboard. Attach using pocket screws.

The base of the panel is a reclaimed 2×6 cut down to 55″.

The length of the pocket screws is determined by the thickness of the material. The nominal or actual thickness of a 2×6 is 1.5″. So the proper pocket screw length is 2 1/2″. I used my Kreg Jig Jr. for this project.

Look at that! It’s starting to look like something other than a pile of wood panels.

Now it’s time to attach the legs. The legs are simple 2x4x8 studs cut down to 50.” I attached the legs of the headboard using 2 1/2″ pocket screws.

Ok….I made a mistake here. I turned the headboard back over to see my work and well… There is a good side and “bad” side to lumber. The bad side or rather the side that should be facing down is the side with the specs of the lumber written on it. In cases where you are staining your headboard with a lighter tone…this matters. But if this happens to you too, don’t fret, just take out your sander like I did and sand it away. Mistakes happen. But it’s how you come back from your mistakes that mater the most.

Once I’d sanded my mistake I turned the headboard back over to attach the legs of the headboard.

At the top of the headboard I attached another piece of 2×6 cut down to 62″ spanning the width of the entire headboard using pocket screws.

Now flip the headboard back over. Be Careful. This darn thing gets heavier with every piece.

At the very top of the headboard place the 1×3 over top the 2×6. It should be 64″ in length, overlaping the board by 1″ on either end of the top.

Attach using finishing nails or your brad nailer.

There you have it, your basic panel headboard!

Now lets make it pretty. In this portion I can’t provide the exact measurement for the trim. The trim used is a personal preference and is cut to fit. So have fun at your local hardware store. The beauty is in the detail.

Once the trim and moulding was complete I flipped the headboard over once again. This time very gently and with the assistance of a friend. I decided the best way to keep this headboard up was to attach it to the wall. So using a french cleating system, I made cut a 2×4 down to 40″ and cut it in half at a 35 degree angle. I made my french cleat out of wood. But it can also be purchased from a hardware store or Amazon, like the Hangman French Cleat.

Now it’s time to clean up this headboard. I used reclaimed wood. So it naturally had its nicks and scrapes. Using wood filler and a putty knife fill in the holes and “imperfections.”

Once it has dried, sand down the headboard and prep for staining or painting.

So my friend asked that her headboard be stained black. It pained me to cover that beautiful wood with such a dark stain. But I used a glossy finish and it actually grew on me.

Set the headboard against the wall to measure the height of the cleat board installation.

Attach the opposite cleat to the wall ensuring that its screwed in to the wall studs. A stud finder is very useful in this situation. As a rule of thumb, studs within the wall are normally 16 inches apart.

Ok place your bed and box spring up against the headboard and make the bed. Enjoy a beautiful night’s sleep in a bed you created. Should you have any questions or concerns or even tips or pointers, please leave me a comment. I’d love to hear from you.

Ok place your bed and box spring up against the headboard and make the bed. Enjoy a beautiful night’s sleep in a bed you created. Should you have any questions or concerns or even tips or pointers, please leave me a comment. I’d love to hear from you. Till Next Time! ~T.

Till Next Time! ~T.